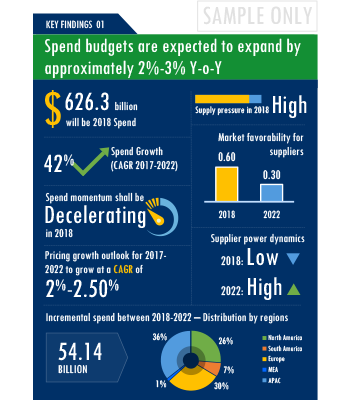

The report provides a comprehensive coverage on Polycarbonate category spend growth and regional spend segmentation insights, Polycarbonate price trends and Polycarbonate supply market analysis.

GET FREE SAMPLEPolycarbonate is an essential part of the Engineering Materials category which includes all spend related to the provision of essential industrial and engineering raw materials which are further processed or used to produce goods, articles or structures.

The market for Engineering Materials and its sub-segments such as Polycarbonate are at an interesting intersection. Volatility in the prices of key inputs is creating multiple issues that impact procurement within Polycarbonate category such as benchmarking and budgeting of the procurement costs.Markets across the globe are reeling under shortage of professionals and workforce that have relevant skills and training. Minimum wages and stringent regulations are compelling suppliers to increase their employee expenses which are expected to have an inflationary impact on buyers' procurement cost.Suppliers of Polycarbonate are moving up the value chain - both organically as well as through M&As. Their portfolios are increasingly being diversified with the objective of offering integrated solutions that go beyond just Polycarbonate. Even buyers are engaging vendors who can act as a one-stop solution provider across their geographic footprint. Such strategic engagements can help buyers with savings associated with economies of scale and management of a much smaller supplier base.Trends like these and many others discussed in this report are necessitating a relook at the way Polycarbonate is procured and the procurement cost saving opportunities that exist.

As market conditions become more dynamic and procurement practices get more sophisticated, category managers need to be cognizant of the best practices that work for their Polycarbonate category procurement. The report offers a succinct analysis of Polycarbonate procurement best practices. For example, Buyers should engage with suppliers that have recycling capability. Recycling capability of the suppliers will lower their production costs which will be passed on to buyers. Additionally, the recycling capability will contribute in furthering the sustainability goals of the buyers' organization. Competitive bidding as a cost optimization tool is extremely potent but should be carefully deployed only when there is no significant differentiation among Polycarbonate suppliers. Buyers should engage with suppliers that repurchase used products at fair market value. This assists buyers to dispose of used products in a convenient manner. Also, during such repurchases, suppliers provide credits to buyers for future purchases. This reduces overall procurement costs for buyers.

Activate your free account to gain easy access to cutting edge research and insights on consumers, emerging price trends, global and regional suppliers.

Polycarbonate procurement managers also need to proactively identify and mitigate potential risks that can arise in the supply chain or contracts for Polycarbonate procurement. Some examples include:

For detailed insights and complete access to our report library, activate your free account!

The report is intended to serve as a one-stop reference guide for Polycarbonate procurement strategy and offers a perfect blend of category basics with deep-dive category data and insights. Therefore, it is ideal for category beginners looking for “Polycarbonate: Procurement Report 101” as well as for category experts actively tracking the global Polycarbonate procurement market.

You may have just initiated your research to design a winning Polycarbonate procurement strategy, or you may be a category expert looking for strategic insights and updated data.Either ways, the report has your requirements covered.

Unlock SpendEdge's comprehensive procurement report collection with ease through our procurement platform.

Procurement decisions can prove to be costly in the absence of careful deliberation and evaluation of every available option. In fact, more than 90% of the decision makers we work with acknowledge that timely availability of up-to-date category intelligence can help them make better purchasing decisions. More than 80% of them believe that in-house category intelligence needs to be updated periodically to achieve full benefits. If you have read so far, we are quite sure you agree!!

The Polycarbonate procurement report helps take more informed decisions by placing all the critical information and advice at the fingertips of a decision maker. It also specifically answers some of the key questions that we have been routinely asked during our industry outreach initiatives:

SpendEdge Insights has helped procurement professionals and sourcing teams manage multiple spend areas and achieve more than $2 billion in savings. Activate your free account today!

The Polycarbonate market report offers a complete picture of the supply market and analyzes the category from the perspective of both buyers and suppliers. Analysis of the category trends, procurement best practices, negotiation levers and overall category management strategy advisory are interspersed with in-depth data and commentary on spend outlook, pricing ecosystem and supplier landscape drilled down to a region-level coverage.

A key highlight of this report is the in-depth outlook created on Polycarbonate procurement spend and pricing trends. The report further delves deep into the aspects of cost structure, total cost of ownership and supplier margins for Polycarbonate. A dedicated section to supplier profiles and evaluation helps decision makers cast a wider procurement net and identify gaps in existing relationships.

Along with specific category and supplier intelligence, the publication also includes curated insights on Polycarbonate market trends, price influencers and inherent risks. These insights help the decision makers prepare for market shaping trends in advance and create alternative strategies for changes in the market conditions.

Additionally, the report also advises on the best practices and strategies to manage the Polycarbonate category efficiently. Negotiation levers and opportunities are explained in detail along with quantification of their potential. Benchmark KPIs for supplier and buyer performance management are also aggregated to better organize the category objectives. Other themes of advisory include ideal procurement organization structure, enablers to achieve KPIs or category objectives and ideal SLAs to have with suppliers.

Our research is complex, but our reports are easy to digest. Quantitative analysis and exhaustive commentary is placed in an easy to read format that gives you an in-depth knowledge on the category without spending hours to figure out “what does it mean for my company?”

SpendEdge presents a detailed picture of Polycarbonate procurement solutions by way of study, synthesis, and summation of data from multiple sources. The analysts have presented the various facets of the market with a particular focus on identifying the key category influencers. The data thus presented is comprehensive, reliable, and the result of extensive research, both primary and secondary.

Global Methacrylic resins Market - Procurement Intelligence Report

Global Vinyl Acetate Polymers Market - Procurement Intelligence Report

Global Polyurethane Synthetic (PU) Leather Market - Procurement Intelligence Report

Global Urethane Market - Procurement Intelligence Report

Global Resins Market - Procurement Intelligence Report

Global Acrylonitrile Market - Procurement Intelligence Report

Global Polyamide resins Market - Procurement Intelligence Report

Global Silicone Rubber Market - Procurement Intelligence Report

Global Polyvinyl chloride polymer Market - Procurement Intelligence Report

Access this report and our entire procurement platform | Plans starting from USD 3000/ Year Buy Now

Copyright © 2025 Infiniti Research Limited. All Rights Reserved. Privacy Notice – Terms of Use – Sales and Subscription

Cookie Policy

The Site uses cookies to record users' preferences in relation to the functionality of accessibility. We, our Affiliates, and our Vendors may store and access cookies on a device, and process personal data including unique identifiers sent by a device, to personalise content, tailor, and report on advertising and to analyse our traffic. By clicking “I’m fine with this”, you are allowing the use of these cookies. You may change your settings based on a legitimate interest at any time, by selecting “Manage Settings” on our site. Please refer to the help guide of your browser for further information on cookies, including how to disable them. Review our Privacy & Cookie Notice.